Manufacturing Process of Jersey Barriers

Step 1. Steel cage is prepared with 10MM & 8 MM TMT Bars

Step 2. Prepare Concrete Mixture in M30 grade.

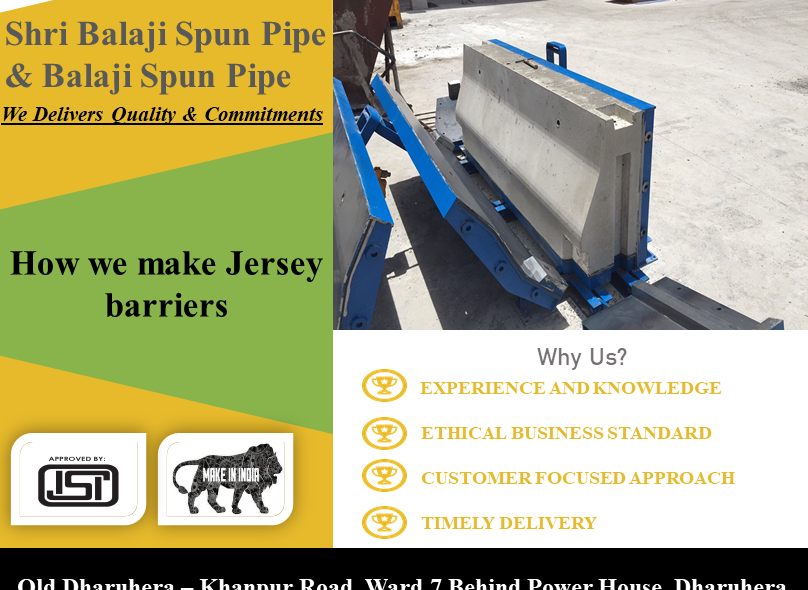

Step 3. Steel Cage is inserted in moulds

Step 4. Assembling of Moulds

Step 5. Filling moulds with concrete mixture

Step 6. Settling mixture in moulds with the help of the Vibration compaction method using FRP for an impeccable finish.

Step 7. Demoulding

Step 8. Finish with a Homogeneous layer of cement plaster 1:1 (Cement & Sand)

Step 9. Curing

Process:

First steel reinforcement cage is prepared with 10MM & 8MM TMT Bars. After that concrete mixture is prepared in M30 grade. Mixing water in the cement, sand and stone will form a paste that will bind the material until the mixture hardens. Once the mixture is ready Mould are assembled and steel cage is inserted in moulds and concrete mixture is fed into the moulds and settle the mixture properly with a vibration table which is called the vibration compaction method using plastic moulds for an impeccable finish. After a while, moulds are removed and Jersey barriers are Finished with a Homogeneous layer of cement plaster 1:1 (Cement & Sand) and after that submersed in the curing tank for 7 days

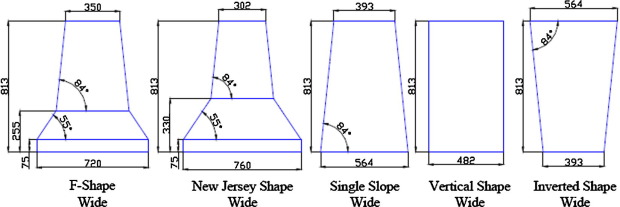

Different Types of Jersey Barriers:

Price of Jersey Barriers:

An F-Shape Jersey barriers cost around Rs.7000 to 8000 Per/Pcs

To Know More Please contact us on:

Mail Us:Sales@balajispunpipe.com|Contact Number:+919992906006

Visit Our Website on www.balajispunpipe.com

Or You can Follow us on LinkedIn