What is Rcc Pipes ?

RCC which is also known as Reinforced Concrete Pipes are large diameter concrete pipes, manufactured using cement, mild steel, grits, dust, cement hardener chemicals water etc. R.C.C. Pipes are manufactured through a very unique method of Centrifugal Casting.

Uses of Rcc Pipes:-

RCC Hume pipes are extensively used for water mains, sewers, culverts, irrigation supply, and in cable management. Owing to its properties subsuming high tensile strength, durability, leak-proof nature, low maintenance, sturdiness, RCC Pipes are widely preferred in the construction industry.

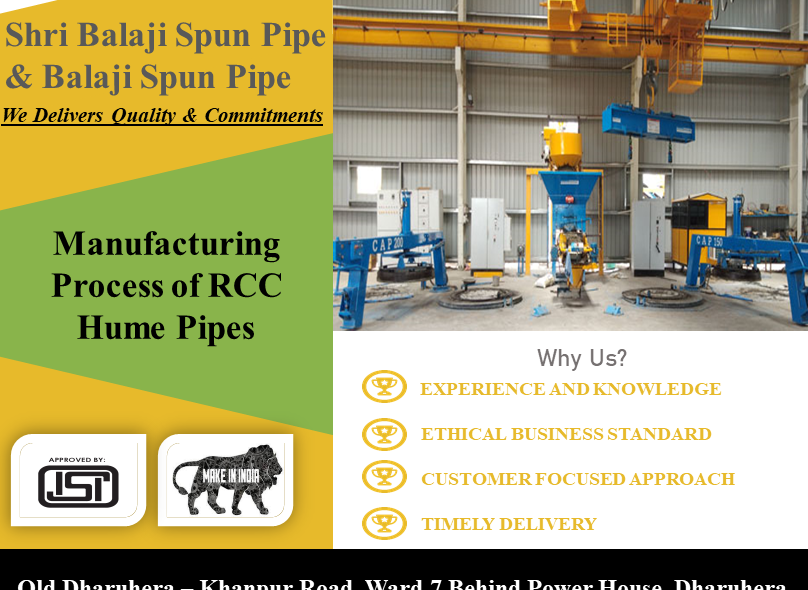

Type of Manufacturing Process:-

1. Spinning Process, also known as Horizontal casting

2. Vertical Casting

There are basically 10 steps of manufacturing of RCC Hume pipes (Horizontal Casting)

1. storage of raw material

2. Assembling of moulds.

3. Preparing reinforcement cage.

4. Mixing of concrete.

5. Spinning of mould.

6. Demoulding

7. Curing.

8. Staking of finished pipes

9.Random test of pipes

10. Dispatch

The Reinforced cage is first prepared on the cage winding machine by hand process. The cage in then placed inside the pipe mould which is then hoisted up and mounted horizontally on the turn unions. It is rotated by driving shaft with variable speed arrangement, the rotation is kept slow in the beginning and then the speed is increased.

The concrete mixture for the RCC Hume Pipes is prepared in the 1:2:5:2:5 of cement stone, metal and sand respectively. The cement concrete is fed into the moulds during rotation which spreads inside evenly. The time required for completion. The pipes 24 hours. On the following day pipes are removed from the moulds and submersed in the water in the curing tank for about 7 days depending upon the class of the pipe.

To Get the Latest Updated Rate Please contact us on:

Mail Us:Sales@balajispunpipe.com|Contact Number:+919992906006

Visit Our Website on www.balajispunpipe.com

Or You can Follow us on LinkedIn